- What We Do

-

-

-

WHAT WE DO

Our Fully Integrated Services

We manage your project from property selection, through design and construction and when the project is complete, provide ongoing facility management.

-

-

-

- Our Work

-

-

-

FEATURED PROJECT

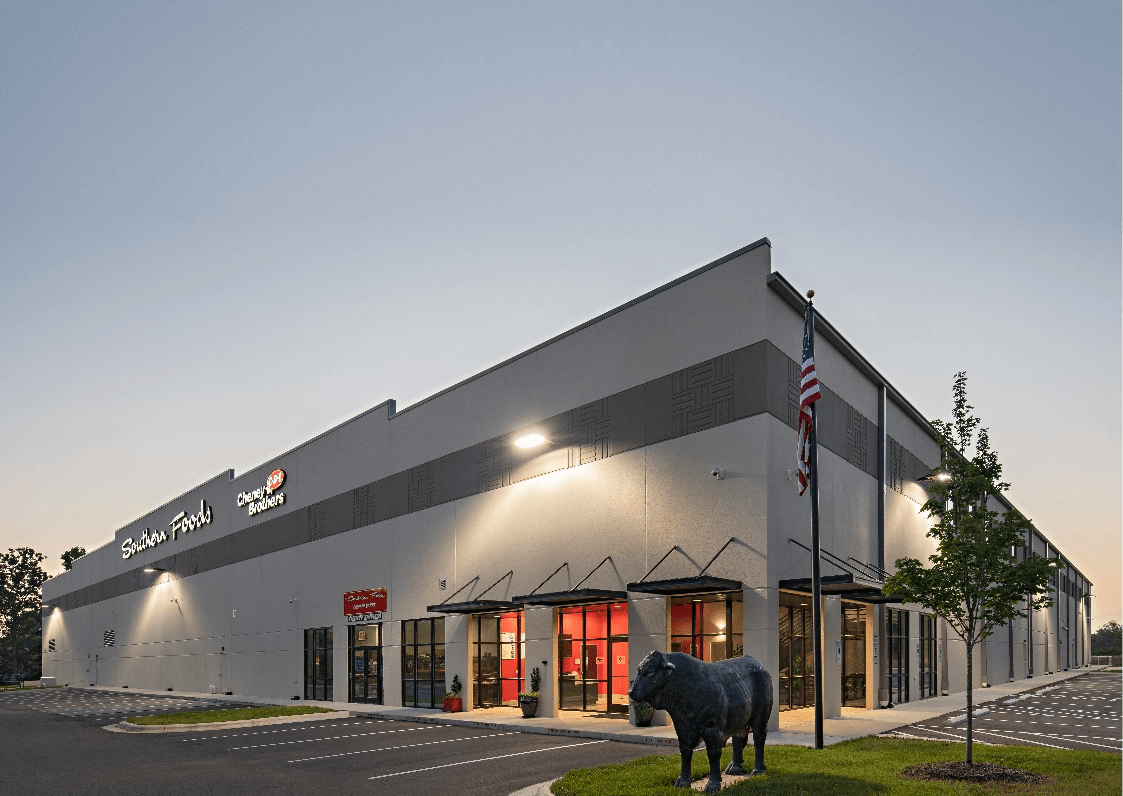

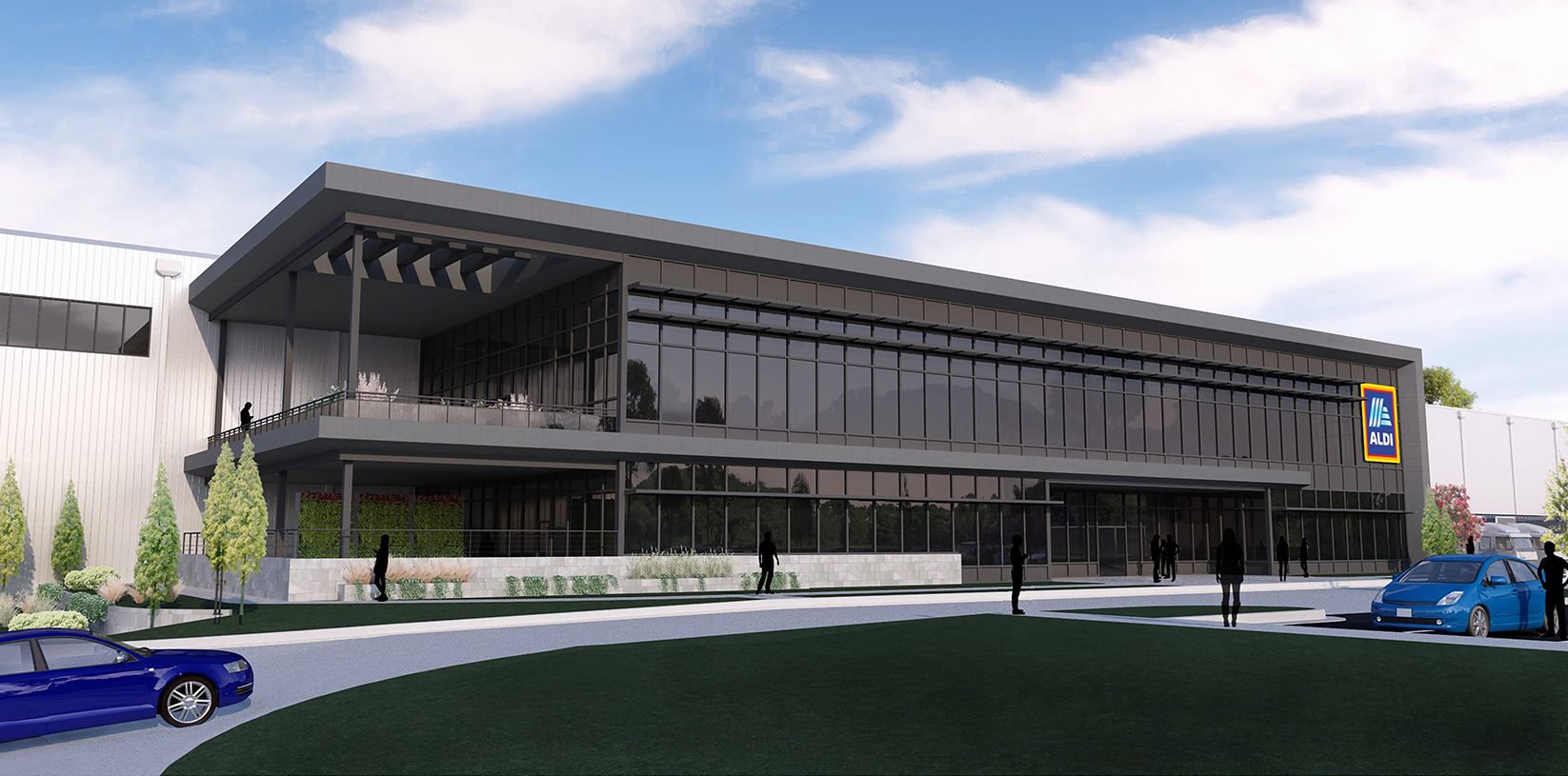

ALDI Loxley Regional Headquarters & Distribution Center

A M King provided property consulting for ALDI US and designed and built the regional…

View Project

-

-

-

-

- Insights

-

-

-

FEATURED INSIGHT

The Secret to Exceptional Sanitary Design

What is the secret to exceptional sanitary design for a complex food processing facility? I…

View Blog

-

-

-

-

- About Us

-

-

-

ABOUT US

A M King

A M King is an employee-owned, integrated Design-Build firm strategically focused on the food processing, food distribution and cold storage, industrial, and corporate markets.

-

-

-

Have questions? Schedule a discovery call 704-365-3160

Have press and media inquiries, please email [email protected]

- Careers

- Contact