Metal Building Envelopes: With All the Options, What to Choose?

This article originally appeared in Metal Architecture’s Feb. 2021 issue.

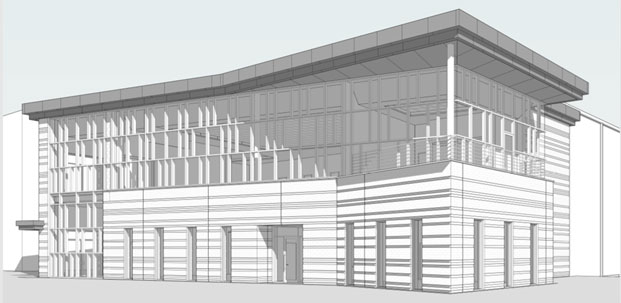

If you are driving from a rural area to an urban area, you pass many different types of buildings. Transitioning from the rural areas, the landscape is dotted with single-story, utility driven, pre-engineered metal buildings. Medical office buildings are common in the suburban areas and then as you get closer to cities, you’ll begin to see high-rise towers. What is one thing all of these may have in common? Metal exteriors. Each application can be similar in outward appearance; however, they can be drastically different in attributes of performance, cost and lead time.

Metal building skins range from 26-gauge fabrication in an industrial shed to multi-function and component assemblies in low- and high-rise construction. If all of these examples use metal building skins and they have the same base component, what are the differences? What applications are most appropriate? Are there very specific industrial environments with temperature-sensitive products demanding the most rigorous process for thermal envelope design and construction? A specific type of metal wall panel may be required. Sometimes all of these conditions exist in the scope of a single, complex project that utilizes metal skin and multicomponent assemblies.

Getting Started

When determining the best strategy for your building, it is important to evaluate the application (commercial, industrial, residential building), detailing (angles, curves, finishing of corners and joints), performance (thermal comfort, durability, maintenance, aesthetic appeal), budget, time, climate and sequence of the construction process. Does your building have complicated angles? Are the building feature corners to be clean and without trim? What allows for dimensional adjustments in the field?

Construction materials play a role in the transfer of heat or cooling from one space to another. It is important to understand the properties of these materials to prevent the intrusion of air, water and vapor into the buildings/spaces being designed. The selection of the outer material is the beginning of moisture management.

To accomplish this goal, several different types of metal wall claddings and assemblies may be considered, including single-skin metal panels, aluminum composite material (ACM) and insulated metal panels (IMP). These systems can be used in two primary types of wall assembly for a building envelope: rainscreen system and barrier-wall system.

A rainscreen system provides a weather barrier interior to the building skin within the wall system. It also acts as a pressure equalizing system between the exterior and interior. In a barrier wall system, the outer skin and weather barrier are one in the same. Both systems are designed to preserve the performance and physical integrity of the building by controlling air, water, and vapor penetration through the wall.

Single-Skin Metal Panels

The single-layer metal panels can be manufactured in several shapes and profiles and fabricated in basically any kind of metal, including common choices such as steel, zinc and copper, as well as differentiated metals like weathering steel.

The single-skin metal panels are durable with coatings to prevent fading and corrosion; however, they tend to be less resistant than ACM and IMP. The building skins typically span between larger spaced girts with no backing except for insulation, making them more susceptible to deformation from impact. This can lead to a compromise of the metal’s coating and ultimately to corrosion and degradation of appearance.

Aluminum Composite Material (ACM)

ACM panels are formed with a polyethylene core bonded on either side by aluminum sheets. They offer high durability, water resistance and can be installed in extreme weather environments. ACM skins can serve as either weather barriers with a wet seal/gasket system, or act as rainscreens with open joints. Application is typically over a cold-formed framed wall with clips or tracks. The tighter spacing of wall support, rigidity of material and the fact that ACM panels are a sandwich assembly of metal, composite and metal give each panel strength to resist higher impacts.

Rainscreen applications of ACM need to be planned for, as the interior weather barrier on the exterior of the sheathing and framing needs to be stronger. For an ACM rainscreen application, a vapor barrier on either side of the framing, depending on climate, is acceptable.

Insulated Metal Panels (IMP)

IMPs are made up of two steel or aluminum skins and a foamed core, such as polyurethane or polyisocyanurate, that form a solid sandwich panel. It is mostly used for walls and roofs, but it can be also used in architectural features like canopies, fascia and soffits. The metal faces are recyclable, the core is reusable, and the panels present a wide variety of colors and textures. The installers must be trained to properly handle this product; however, the simplified fastening systems and lightweight panels provide a fast and less costly installation.

Tips for System and Material Selection

When it comes to system and material selection for thermal control, some items should be always considered:

- Use properly trained installers. Training is widely offered by manufacturers and distributors.

- Understand the climate. It will rule the assembling sequence of a multi-component wall.

- Limit the number of subcontractors by choosing the most simplified, viable option.

- Work with sustainability, considering the recyclability and reuse of the proposed materials.

The materials and wall systems to be utilized for thermal control will always be determined by a range of exterior factors and some of them will be out of our control. However, dedicating extra time in the schematic design to understand the needs and restrictions of the building can result in significant time and money savings, as well as a better organized design process and supplier prospecting.