Integrated Design-Build Delivers in 2021

Design-Build has been on an upward trajectory for years, due in large part to its reduced cost, the opportunity for a more fast-tracked schedule and minimal risk to the Owner. The Design-Build Institute of America (DBIA) reports that nearly half of all the nation’s projects are now delivered using the Design-Build delivery method, in part because it is 102 percent faster than Design-Bid-Build for schedule reduction. The traditional approach of Design-Bid-Build splits design, engineering and construction services into separate entities, separate contracts and separate work.

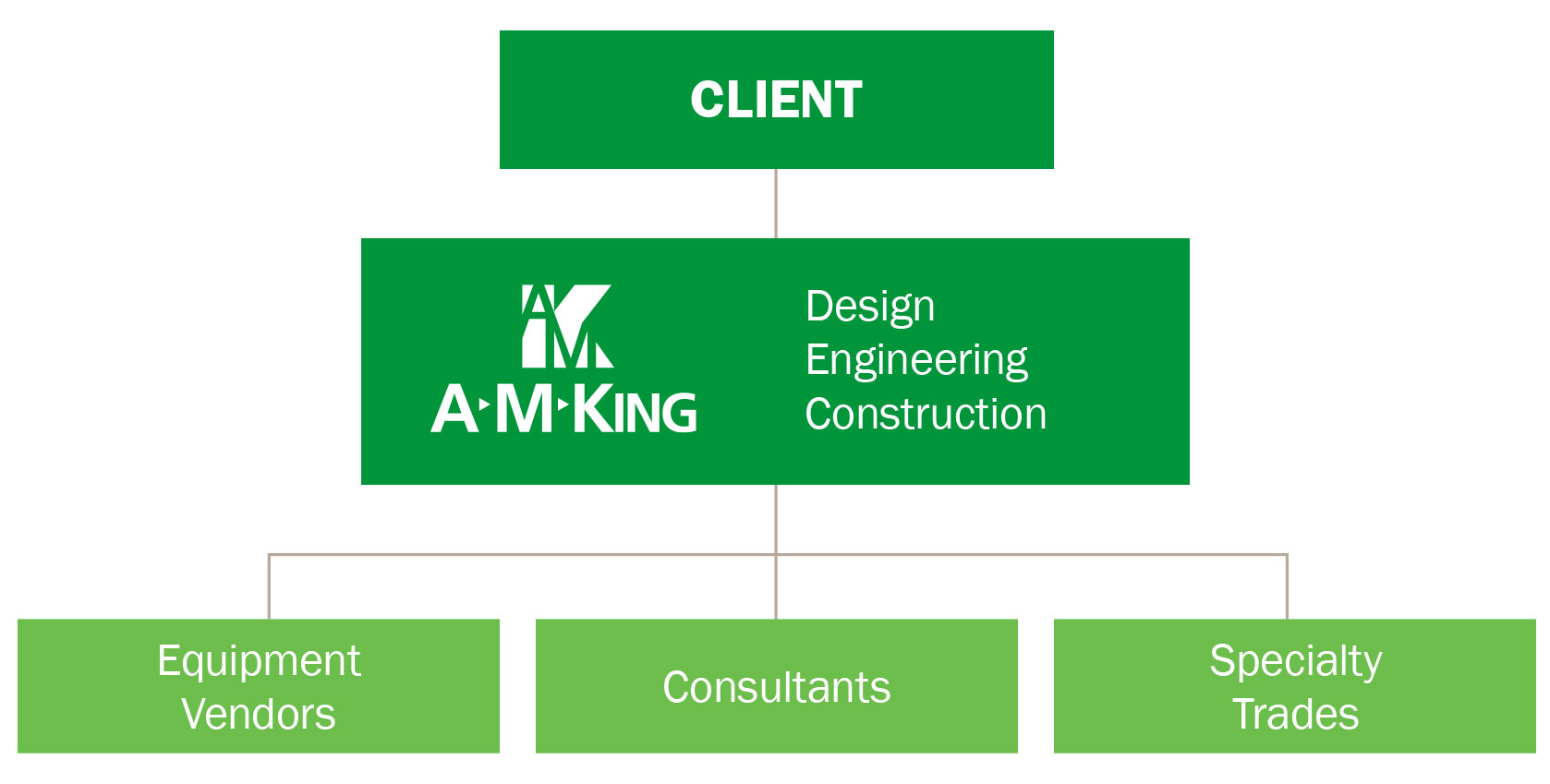

The Design-Build model, in contrast, is defined as a method of project delivery in which one entity—the Design-Build team—works under a single contract with the project owner to provide comprehensive design and construction services. The approach is particularly beneficial for companies with complex facility needs, who may have multiple properties or proprietary processes.

The flexible and collaborative nature of Design-Build has become especially important as the pandemic roars on. Most of our clients in the food and industrial arenas operate essential businesses and must push forward with plans for expansions, renovations and greenfield building projects. Our task, as always, is to accommodate both their need for innovative solutions and their desire to save money. During the best and worst of times, Design-Build shines. Follow that light through this multimedia overview of how A M King interprets and executes Design-Build in an effort to exceed client expectations.

01 / Single Source Contracting

A M King’s fully integrated Design-Build expertise permits the owner the ease of contracting with one firm that has responsibility for the entire project.

A M King has designed a 262,000-sf ripening and cold storage distribution center for Mission Produce almost entirely during the pandemic. The new mega-facility will be in the Laredo, Texas Pinnacle Industry Center on 32.6 acres adjacent to the Rio Grande River and the Mexican Border. It will be the company’s largest warehouse to date, eclipsing the company’s headquarters facility in Oxnard, CA by nearly 50,000 sf. The project, currently under construction, will be complete in May.

02 / Seamless Process

The design and construction teams are integrated under one roof, fostering an atmosphere of trust, transparency and collaboration. This results in a more productive and efficient process. Most importantly, we have satisfied clients, such as Southern Foods, a full-service meat, fish and seafood processing company.

03 / Greater Innovation through Collaboration

U.S. Waffle Company, which outgrew its original facility, purchased a local manufacturing landmark directly south of downtown Liberty, SC for expansion and renovation via Design-Build. The warehouse was built in 1981 and features a 1970s design with reflective glass on the exterior, expansive windows, sizable extensions in front of the main entrance and a large outdoor employee break area. The project is an interesting study in not only how to adapt and reuse an existing building for a new purpose, but also the best way to source repurposed construction materials and baking equipment.

–Rick Stapleton, President, Cheney Brothers Inc. about the Cheney Brothers Statesville Food Distribution Facility.

04 / Competitive Pricing

A M King’s approach to Design-Build secures multiple pricing proposals from prequalified subcontractors and vendors that are, in turn, shared with the client through a transparent process.

ALDI Inc.’s 580,732-sf, award-winning Distribution Center and Regional Headquarters in Dinwiddie, VA serves approximately 70-80 ALDI stores in the Richmond-Petersburg, Hampton Roads and eastern North Carolina regions. “We chose the Design-Build delivery method for this facility based on benefits that included budget management, single-source accountability and optimal collaboration…” –Adam Kastl, Director, Warehouse Development, ALDI Inc.

05 / Change Mitigation

The collaborative process dramatically reduces drawing errors to keep design within cost and budget parameters. Through a single point of contact, the risk of costly design errors is shifted away from the client.

06 / Speed to Market

Research has consistently proven that Integrated Design-Build is the most expeditious method for delivering a completed project. One of our clients, TrueCore, was a startup that needed help with on-site acquisition, design and construction services. Most important, they needed a building completed in time to receive Italian-made production equipment already on order.

“A Design-Build approach was best for us. It gave us the ability to fast-track design, budgeting and construction while overlapping these conventionally sequenced functions.” —Dean Soll, Co-founder, TrueCore

Interested in learning more about our Integrated Design-Build services? Click here to download our interactive brochure.