A Very Cool Conversation about Controlled-Temperature Facilities

If you’re a cold foods manufacturer, what is your No. 1 challenge? Is it food safety, facility efficiency, cost of automation or new technology? And let’s say, for example, that your company is in growth mode and you’re thinking about whether to expand an existing facility or build a new one. Going the greenfield route means that you have to consider how equipment and process will impact design of controlled-temperature facilities.

These are some of the topics I discussed with Kelley Rodriquez, host of Refrigerated & Frozen Foods’ From the Cold Corner podcast during the show’s August 9 episode.

We were joined by Craig Susser, Founder of Craig’s Vegan, a California plant-based ice cream company, and Bob Grote, CEO of Grote Company, an Ohio-based manufacturer of slicing and food processing equipment. I enjoyed talking with these industry veterans who shared some of their goals and challenges, as well as predictions for the cold foods manufacturing sector.

Conversation related to food processing equipment, for example, centered around companies that are interested in flexible automation, preventative maintenance and working with someone who can support them through the entire life cycle of a product line – from the conception stage, all the way to the decommissioning of the line.

From a food manufacturing perspective, the biggest concern is food safety. The ice cream manufacturer is challenged with preserving the original product quality from the time it’s made until the end user customers slide their spoons into the company’s famous Melrose Mint Chip.

We Integrate Property Consulting with Planning and Design

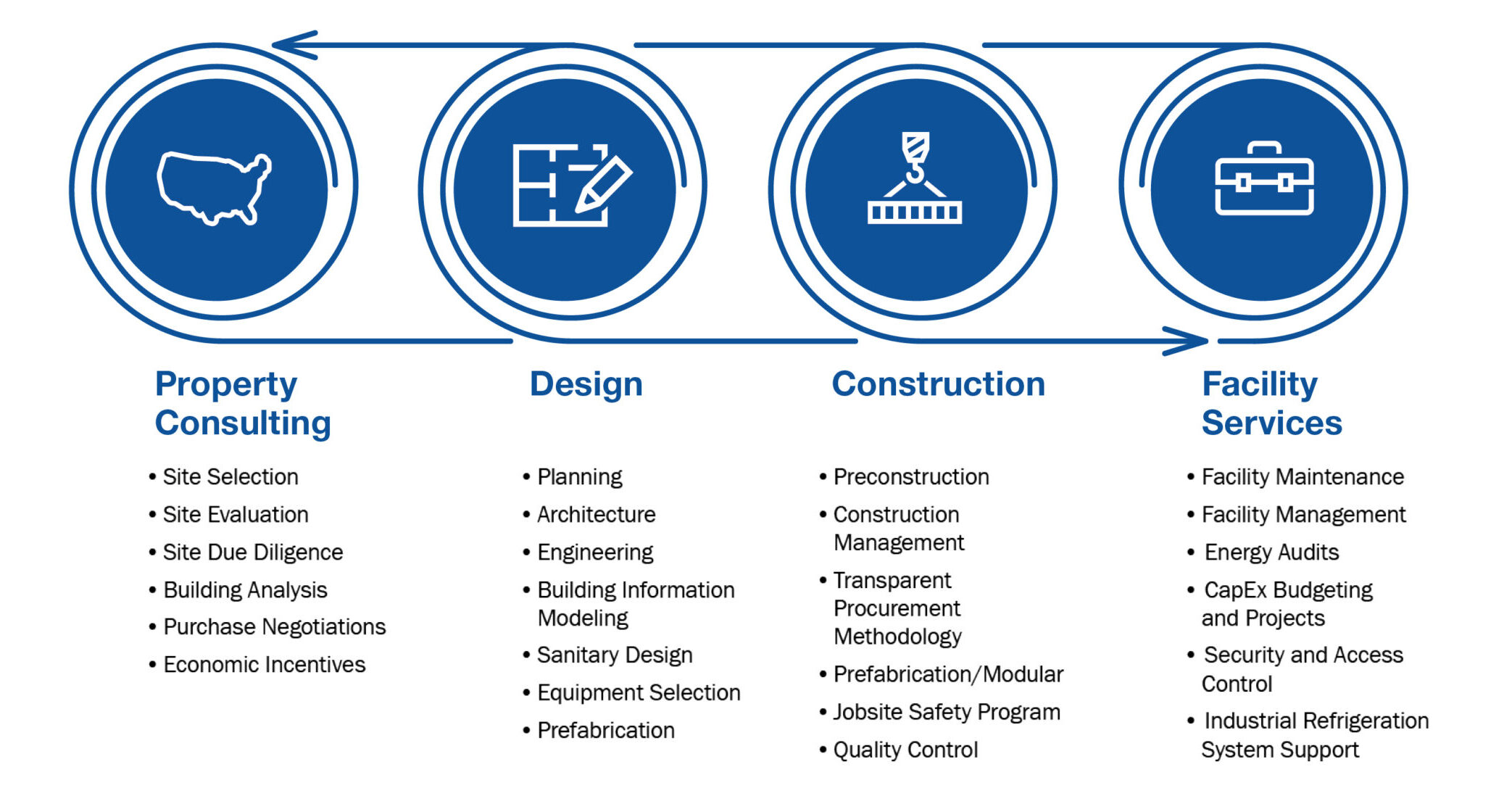

At A M King, we collaborate with our clients from the very beginning of a project to identify, evaluate and acquire property for their next facility. We consider development costs, availability of manufacturing labor, access to supply chain (ports, airports & interstates), and available local & state incentives when it comes to controlled-temperature facilities. Then we move into design, construction, and then, in many cases, we will perform ongoing facility services after the building is completed.

This podcast discussion reinforced that the due diligence we go through at A M King to understand our clients’ needs is paramount to helping them achieve goals for their controlled-temperature facilities. Here are a few of my excerpts adapted from our discussion, along with a couple of case studies.

Controlled-Temperature Food Facility Efficiency

Kelley: David, what are some of the concerns or needs that are specific to cool and frozen food manufacturers when it comes to (facility) design, that ground up philosophy?

David: What we find that’s consistent with almost all of our clients when they start a cold storage or manufacturing facility is that they’re concerned with process efficiency.

Kelley: Yes, when it comes to manufacturing and processing cold and frozen foods just about every part of the facility is important to its efficient operation.

David: We ask how we can improve their process to make product flow more efficiently. How will people access the work and how will employees flow through the facility? We focus on sanitation and how waste will be removed from the building. We focus on proper selection of (building) materials.

When we talk about controlled-temperature facilies, they aren’t just refrigerators. It’s a food facility that handles raw products and it must be cleaned at the end of each shift. We also analyze building performance, considering thermal aspects, durability, dock capacities, pallet positions and storage space. And then clients are always concerned about cost, upfront CapEx expense and ongoing maintenance.

Manufacturing Process Impacts Building Design

Kelley: Speaking of ice cream, David, some food production environments require very specialized large equipment. You know, like an ice cream manufacturer needs blast freezing. How does the type of manufacturing process impact the overall building design?

David: That’s a great question. One of the first things we do during preconstruction is to understand the manufacturing process and get our arms around the equipment that the manufacturer is going to use. It drives everything.

We really cannot start design until we have an idea about the type of Grote equipment that’s going to go into the building to support Craig’s ice cream production goals. (This information) drives the structure, it drives the layout, it drives the type of refrigeration equipment we put in. It drives the utilities that are coming into the building. It has a tremendous impact on controlled-temperature facilities.

These are conversations Kelly, that we have with food manufacturers at the very beginning of the process. At the end of the day, product production and quality requirements are paramount, and the building design / environment must support them.

PRIMARY CHALLENGES: As the pork moves through the Virginia facility, it begins raw, and ends as a ready-to-eat product. Ensuring process efficiency and product integrity were vital for this client.

SOLUTIONS: The processes and equipment informed our design process for this food processing facility project, which included structural and thermal considerations, utility requirements and sanitary design. The size, quality and orientation of equipment, for example, drove the design of the building, Then we molded the building layout around their production process.

Where the product is exposed, for example, there had to be different air pressures and temperatures to eliminate product contamination during each stage of the meat’s journey. We worked closely with the company and their preferred vendors and incorporated the following elements into this project:

- Designed a building layout that would optimize flow of product and employees from beginning to end.

- Designed pathways for robotic product transfer and provided adequate clearance.

- Incorporated properly sloped floors to eliminate standing water and support AGV (Automated Guided Vehicle) traffic.

- Ensured that the facility exceeded company and governmental hygiene requirements.

In addition:

- Utilized building materials that would stand up to frequent cleaning with high temperature water.

- Installed chemical-resistant floors, doors, walls and ceilings that can withstand chemical washdown.

- Designed a custom refrigeration system that can effectively dry these rooms following washdown and prior to the next work shift.

- Coordinated with European AS/RS vendor and local fire codes to create a fire suppression plan.

Sustainable, Automated Controlled-Temperature Facilities

Kelley: What are some of the ways that sustainability is being built into frozen and cold food facilities at this point?

David: A lot of the products today and equipment we put in have an eye towards sustainability. Naturally, people have been making a big migration that way over the last couple of decades.

One key criteria for site selection is always going to be accessing renewable or sustainable energy sources.

We’ll work with the local power company to determine where they’re getting and sourcing their energy from. We’ll weigh that as part of the property selection and then evaluate solar power. You know, a lot of these controlled-temperature facilities have big footprints, hundreds of thousands of square feet, a lot of real estate on the roof that’s ideal for solar power.

Kelley: Convenience and speed are also becoming bigger factors, David.

David: What we’re seeing with automation is automated storage and retrieval systems (AS/RS). If they’re producer Craig they have a multitude of product SKUs, bar codes that they’re having to manage in a cold temperature. So, you’re having these huge warehouse areas that are all automated for the racking. That plays into the height of the building, depending on the commodity and how it’s packaged determines how we provide fire protection for it.

From a building construction standpoint, AGVs put an additional burden on the flatness of the floor and in some of those flooring qualities. Speaking to Craig’s concern, what does it take to get that product from the raw state to what the consumer has in the grocery store? There’s a lot of steps in that process, a lot of things you just wouldn’t consider that go into (development of) a food facility.

PRIMARY CHALLENGES: This client’s chief concern was how to cost effectively increase baking production capacity.

SOLUTIONS: With food facility Design-Build projects, we consider not only process and refrigeration equipment, but if it’s a baking facility like this one, we also collaborate with the bakery owner’s production teams, quality control teams and automated equipment vendors to determine the optimal building layout.

For this Indiana facility project, we discussed the following issues that informed our strategy for helping the client achieve their goals.

- Established client production goals and budget ceiling to maximize both efficiency and spending.

- Determined where the dry ingredients should be stored and how and where they should be transferred to the area for making dough.

- Identified how the products are proofed, baked, cooled, and packaged and how they should be transferred to the next stage.

- Defined automated elements that best fueled company processes.

- Incorporated automated systems related to ingredient transfer, conveying and freezer storage.

Conclusion

Controlled-temperature facilities are complex buildings. Whether we’re designing and constructing a new food facility, or renovating and expanding an existing building, there must be intense collaboration among our Design-Build team, the production managers, and the process and automation vendors. Getting all these players together on Day One is critical for ensuring that the finished facility is exceptional, innovative, sanitary, efficient, cost effective, and exceeds all owner expectations.