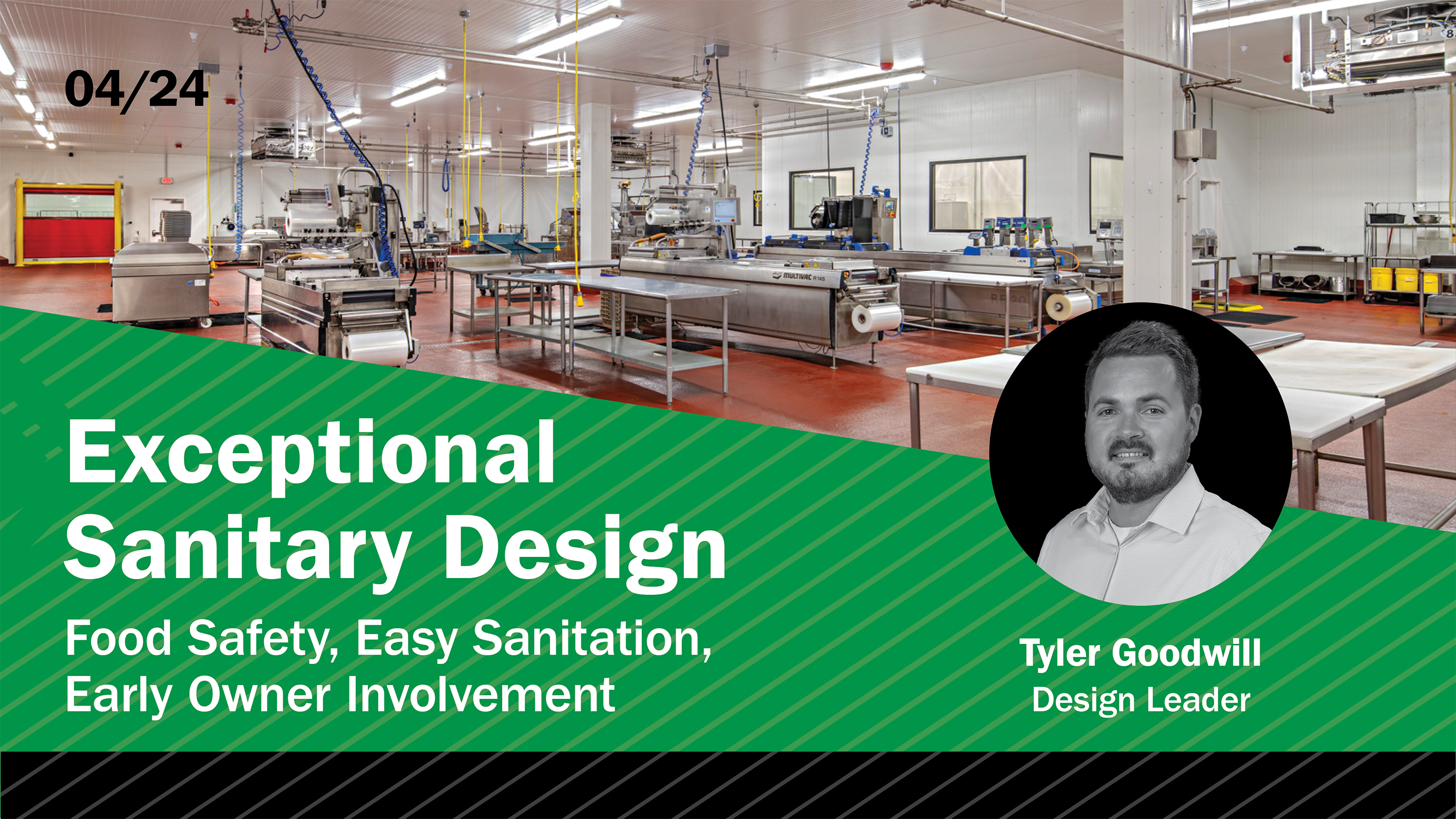

The Secret to Exceptional Sanitary Design

What is the secret to exceptional sanitary design for a complex food processing facility? I could say it’s FSMA compliance; process flow, air flow and hygienic zones; building components and construction; or automation. All of these elements play a critical role in a comprehensive plan, but how we involve clients in this strategy maximizes their potential for success as end users.

Sanitary design is sometimes referred to as hygienic design. Sanitary/hygienic design is the practice of designing and constructing food facilities to minimize contamination risks and enable effective cleaning and sanitation.

We don’t view sanitary design as an afterthought or an add-on service. Sanitary design must be integrated with facility planning from the very beginning of a project. Addressing it when construction begins or at the clients’ production start is too late.

I’ve been working with two new clients in different food processing submarkets recently, fish processing and baking, respectively. The former is pursuing development of a greenfield facility and the other a major renovation/expansion. In each case, I met with them early and often in the design process to discuss their business goals and facility challenges, and of course, issues related to food safety.

Superior design will always safeguard against microbiological hazards, facilitate easy sanitation maintenance, and protect product integrity. It should also anticipate change in client business models, setting them up for a productive and profitable future.

Someone once told me that hygienic design work isn’t exciting, but I strongly disagree. I’ve been designing food processing and food distribution projects for more than 16 years and I have become more passionate about this line of work as I gain more experience. What follows are some of A M King’s top considerations for thorough sanitary design, including some of the elements we are incorporating with our newest clients and how they will benefit.

Why Sanitary Design?

I’ve been working in the food industry since my first job as a busboy when I was a pre-teen. I went on to work at grocery stores stocking shelves and eventually managed a frozen food department. My mom, sister and I collectively have 78 years of employment in the cold storage industry, so I am particularly attuned to the challenges of maintaining product integrity.

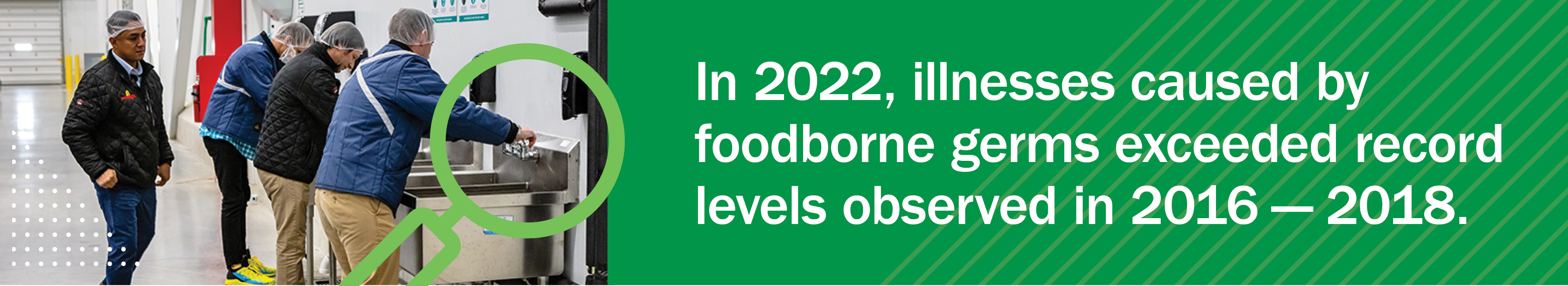

The Centers for Disease Control (CDC) estimates that each year 1 in 6 Americans gets sick from contaminated food or beverages and 3,000 die from foodborne illness. In 2022, illnesses caused by foodborne germs—E Coli, Salmonella and Listeria—exceeded or returned to levels observed in 2016-2018, a time period which saw the most cases of multi-state outbreaks in 20 years. The removal of many pandemic era interventions has resulted in a resumption of illnesses, international travel and other factors leading to intestinal infections.

Foodborne sickness can be prevented in part by food processors recognizing and reducing contamination hazards in their operations. While the FDA routinely inspects food facilities and sets forth guidelines such as the Food Safety Modernization Act’s (FSMA) Final Rule, implementing sanitary design best practices — and working closely with food companies to integrate those practices into their operations —remains one of the best ways to avoid contamination in a food facility.

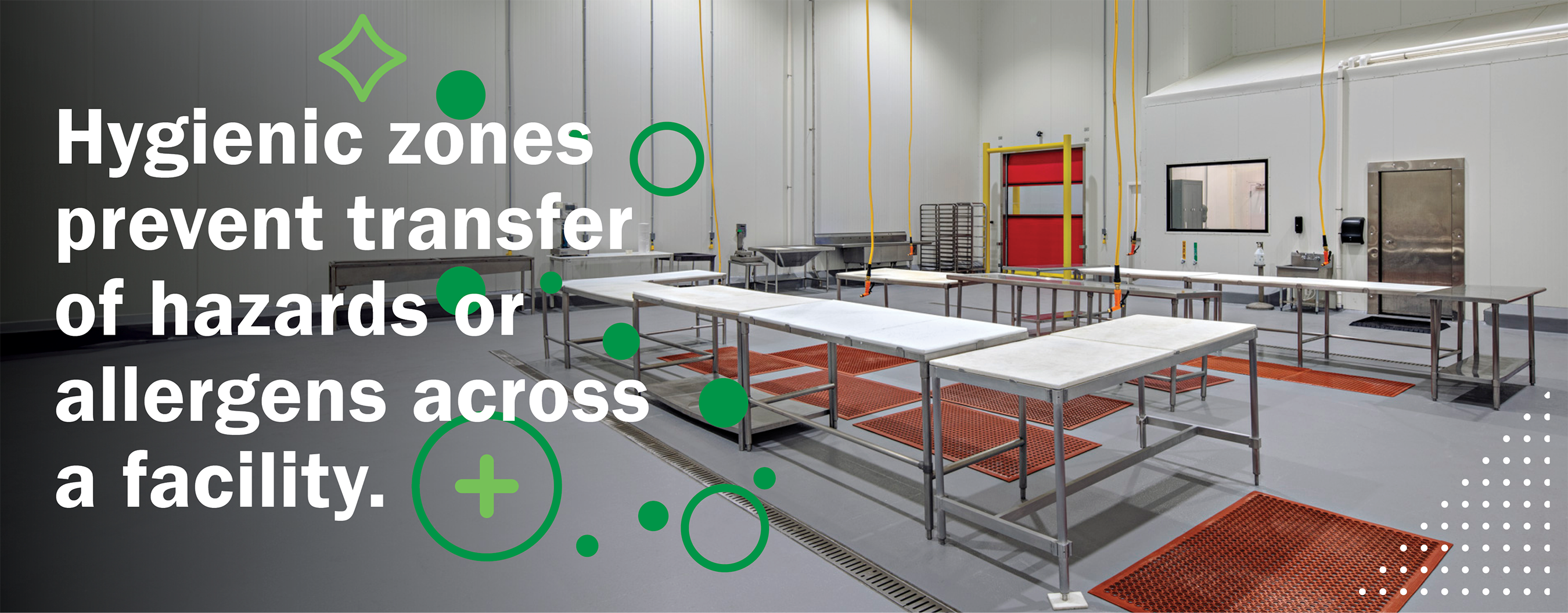

Hygienic Zones/Material and Personnel Flow

As part of our design process, we create hygienic zones in food processing facilities through physical separation, which is becoming a more frequent practice for ensuring food safety. It is imperative to reduce the likelihood of transferring hazards and allergens between different areas of the plant or process. For example, adding physical separation between process lines can help with wash-downs and/or prevent cross contamination.

On the aforementioned seafood processing facility project — the company’s first in the U.S. — I met with the Owner’s Food Safety Quality Manager to discuss the facility design and we began considering critical questions:

How should material and personnel flow throughout the facility? What rooms will accumulate water via the process or wash-downs? What are the room temperature, humidity, airflow, and air quality requirements? Can we provide space to promote sanitation? What zones will have special material requirements? How should the mechanical, electrical, and plumbing (MEP) systems be designed to prevent contamination? And lastly, how can we integrate a sanitation program into the building design?

During the initial meeting, as well as through subsequent discussions, we discovered key information about the company’s process for transferring materials.

Because they would receive fish in three different forms (frozen smoked fillets, whole fresh fish, and fresh fillets) each will need to take a different journey through the facility. Our challenge was to create pathways, spaces and conditions that will ensure product safety.

For example, the fresh fish would take one of two paths that require distinct processing and packaging spaces:

1. Cold or hot smoked, frozen in a spiral freezer, sliced, packaged/labeled, stored and shipped.

2. Grilled, cooked via sous vide, then packaged/labeled, stored and shipped.

Fish moving down the second path would require a dedicated refrigerated space for the griller/flamer with an extraction fan that pulls air from the environment in and around the grill, then up and out of the facility. To use this equipment in a refrigerated space, we worked with the client and our refrigeration vendor on a custom system, including a mixed-air unit that would bring in recycled and fresh air to supplement the removed heat.

Per the sous vide process planned for this facility, the fish is then transferred to a robotic packing system, before going into a vacuum seal machine, a lazy-river style cook tank, and then on to the freezers and separate storage for ready-to-eat (RTE) product.

Our design for personnel flow began with separate welfare areas for those who work with raw fish versus those who work with RTE product. We also implemented an equipment and personnel corridor the length of the facility so workers can bypass spaces without traversing through them. Finally, we identified the best locations for hygiene vestibules, necessary transition areas that allow for materials and/or handlers to move safely from one hygiene level to another.

Building Components & Construction

The methods and materials used to construct a building can also facilitate sanitation in food facilities. It’s imperative to prevent harborage points, ensure sealed joints and the absence of voids, and to use durable components that can be properly cleaned. We carefully select materials for the floors, wall finishes and coatings, and items such as walk-on ceilings.

Our newest bakery project is for a Midwest-based baking company that is adding another line to their Indiana bakery. During my first tour of their existing facility, I noticed accumulation of flour dust on the floors and overhead horizontal surfaces — primarily produced during the dough mixing process.

The exposed roof structure, including utilities and light fixtures suspended above the process equipment, increased the surface areas which require attention during the sanitation process. The owners were extremely interested in a design for their new expansion space that could be more efficiently cleaned and maintained and would promote food safety.

My team and I decided to focus on utilizing certain building components and construction methods to facilitate and exceed the desired sanitary conditions, and I shared our early conceptual sketches with the owner to illustrate this strategy.

Flour dust generated during the dough mixing process is inevitable, so in the new bakery design, we introduced a physical separation, or hygienic zone, to contain the dust to that area of the plant. Next, we introduced an interstitial space, or walk-on Insulated Metal Panel (IMP) ceiling, over the entire process area.

With an interstitial space, we’re able to separate process areas from utility services and overhead structural components. Utility services above the IMP ceiling can be routed horizontally to a location within the plant that can then drop vertically to their required connection point. This strategy significantly reduces the number of horizontal surfaces within the process areas.

To resolve the light fixture issue, we specified recessed fixtures with top access from the interstitial space — eliminating the horizontal surfaces that come with suspended light fixtures and the need for cleaning and maintenance via scissor lift in the process areas.

These strategies will benefit the company by reducing contamination risks and downtime for sanitation and/or maintenance, and serve as a blueprint for future expansion.

Building the Best Partnerships

All of A M King’s food processing clients have something in common — they want to expand production safely and efficiently. However, they each have goals, processes and concerns unique to their business, which vary dramatically depending on which food submarket they are in (meat, produce, bakery, etc.).

We work closely with the owner’s team to understand their concerns related to sanitation and food safety, and create innovative solutions that address their challenges. Those might include infrastructure for sous vide operation and easy sanitation maintenance, but we might also suggest elements such as sloped floors, temperature monitoring or Clean-in-Place (CIP) systems.

The key is developing a strategy for sanitary design in concert with the overall design process. The sanitary design/hygienic design, we develop, in collaboration with the client, becomes part of the foundation of the design and does not get lost as the design continues to develop.

This approach promotes client trust and confidence in our Design-Build experts’ ability to provide the best process flow and building components for a superior sanitary facility. Equally important, by engaging our clients from the outset of design, we help position them for success as the end user.