How to Mobilize BIM for Facilities Management

Imagine trying to renovate a house without knowing where the plumbing is. Now take that example, put it on steroids and you’ve got a complicated situation for sizeable facilities with food processing or manufacturing equipment. But it doesn’t have to be that way.

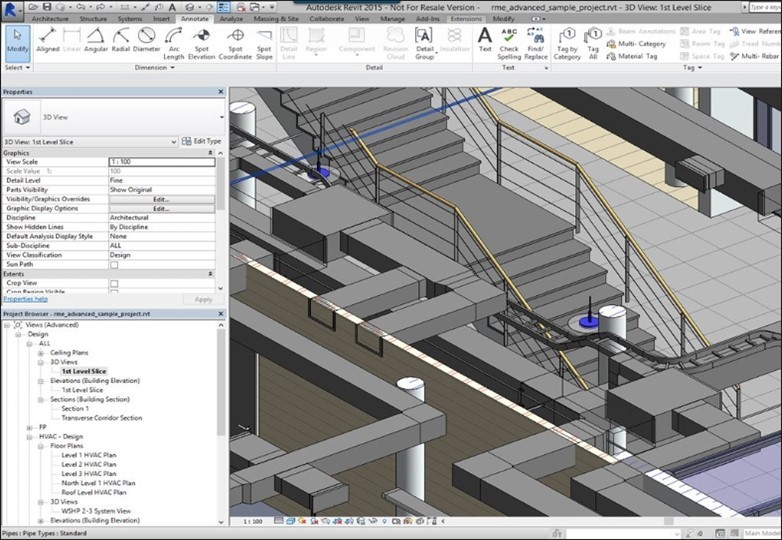

We’re working with a large company in South Carolina serving the automotive, aerospace and energy industries that decided to invest in a basic Revit model of its primary manufacturing facility. The model included structural steel, floor, roof and walls. As projects are implemented around the facility, the model is updated with new equipment layout and utility information—providing an ever-improving, as-built model of their facility. This “eat the elephant one bite at a time” approach enables facility managers to move forward in leveraging the capabilities of Building Information Modeling (BIM) in an efficient and effective manner. As the model evolves over time, the intent is to add more information, such as below-grade foundations, underground utilities, and embedded data for equipment utility requirements (power, process water, process gases, etc).

BIM, a powerful tool that provides a comprehensive digital representation of the physical and functional characteristics of a facility, can be used to make informed decisions for asset management, space planning, energy consumption and cost efficiencies. Many companies, having already realized the benefits of BIM during design and construction of projects, are now learning to drive the technology through the entire lifespan of the structure.

An IMAGINiT Technologies survey conducted in 2017 reports the percentage of building owners integrating BIM data into a facilities management system increased nearly 8.9 percent—from 6.1 percent to 15 percent. Adoption of BIM is usually at a more basic level though, with 90 percent of facility owners seeking space information from the models. For example, during this same time period, 10.7 percent more owners indicated they want point cloud data as part of model deliverables.

It’s obvious why interest in BIM for FM is increasing. If integrated properly, it can provide accurate as-built information for renovation projects; reduce operational costs and change orders; and increase efficiency and collaboration. However, significant challenges remain in using the technology for managing building operations. In some cases, organizations are not prepared or equipped to make the process and technology changes required for a complete BIM implementation. There also may be resistance from internal end users that are not educated about the process. That’s why we counsel owners to take small steps that will address persistent frustrations.

Would you answer yes to any of these questions?

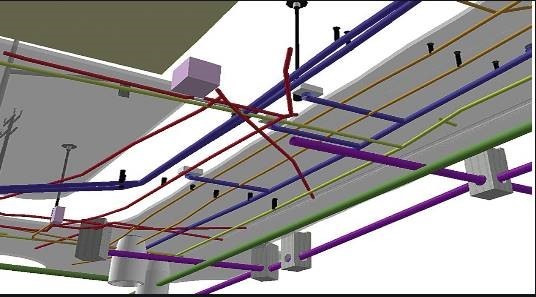

Tired of poor or nonexistent as-built drawings? A recent renovation project at an industrial facility required removal of the existing argon gas lines, but there were no drawings that specified where the lines were located. Thus, the company had to first pay for creating the drawings so that they could then price the demolition work.

Worried that the only person who knows where all the underground utilities are located is about to retire? Don’t kid yourself. This happens every day.

Don’t have the funding to develop an as-built BIM model or worried it’s too complicated? It doesn’t have to be either.

Let’s get started then with this simple approach:

Scan and create a point cloud of your existing facility. There are more and more companies offering this service and it’s not as expensive as you might think.

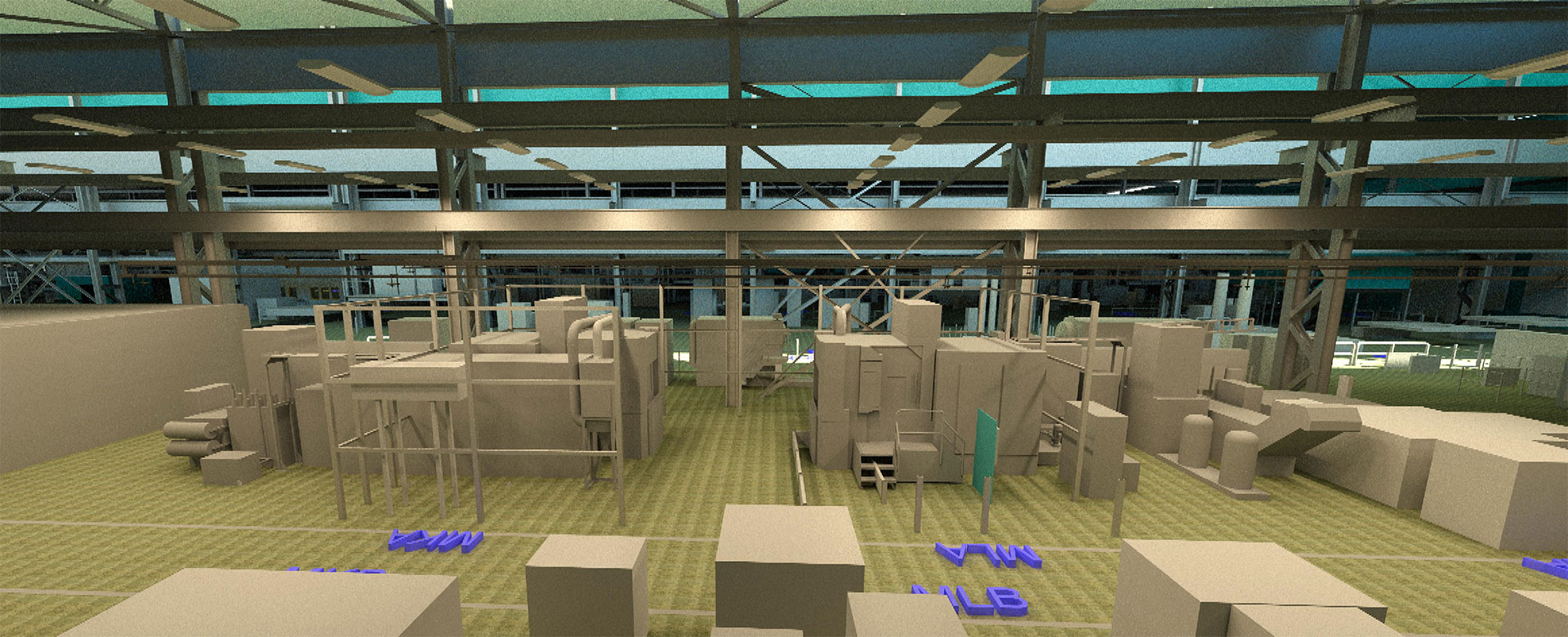

Model as you go. You don’t need to model the entire facility and all utilities at once. As projects come up, model only what you need from the existing point cloud. For example, it might just be floors, walls, structure and MEP over 2” in diameter at the bays where your project is located. With a point cloud in hand, this can be less expensive than having to create an as-built of existing conditions from scratch. Over time you will work your way around the facility and eventually stitch together a full, as-built model.

Develop a BIM maintenance plan. This is similar to a BIM execution plan for new projects, but simply documents where the point cloud and model will be hosted. It also covers the process for updating the model with any new project info and/or maintenance ticket work that might impact the as-built model.

Establish a model manager. This can be an internal resource, or you can outsource it to a trusted partner.

Be disciplined in implementing your BIM maintenance plan. The model will only be as good as you make it.

Include underground utilities and foundations in the plan. If you have congested areas of underground utilities, consider investing in mapping those utilities and including them in your as-built model. This effort will more than pay for itself by avoiding unplanned disruptions to your operations.

Consider BIM’s safety applications. Use BIM to animate the installation process for getting a large piece of equipment in or out of the facility safely. This will ensure the equipment will make it around tight corners and not conflict with any overhead utilities in the plant.

BIM is a powerful technology and there is so much you can do with it. There are a lot of smart people developing very sophisticated, yet overwhelming, applications that can absolutely make people’s heads spin. Over time that will decrease, but right now just get comfortable with the basic concepts and uses for BIM. Don’t avoid engaging with it because it scares you. There is simply too much potential.