Why Design-Build Works in the Automotive Industry

I’ve been using a lot of car analogies since I’ve been working on projects at ZF Transmissions Gray Court (ZFTG).

I was recently asked to describe A M King’s Design-Build approach to someone in the manufacturing industry who only has experience working with general contractors. I immediately thought about the number of designers, engineers, suppliers, transporters, quality inspectors and assembly line workers, among many others, that it takes to build a car. The automobile company manages those people, the planning and the processes that go into the development of a vehicle. It’s a complex progression but if executed properly, the end result could be a sleek, red, EV model with dynamite performance, features and safety ratings.

Similarly, A M King also manages every aspect of a design and construction assignment for our clients. Whether it’s development of a greenfield facility, an expansion/renovation, or delivery of a CapEx project, we seamlessly and efficiently take that vision from concept to completion. During the course of the project, our in-house integrated, Design-Build team works with our subcontractors, vendors, suppliers and consultants to accomplish a staggering number of formidable tasks. Our final product, the successfully completed facility, is the red roadster that’s as impressive under the hood as it looks on the highway.

What’s Driving Auto Industry Growth?

During A M King’s history, we have successfully completed thousands of projects for manufacturing clients in the energy and aerospace industries, such as GE Gas Power and Honeywell Aerospace. These projects, and the lasting client relationships we have built, have paved the way for more recent work in the booming automotive sector.

Demand for automobiles is higher than ever and interest in the electric vehicle (EV) market is fueling much of the recent growth. In 2021, automakers announced $36 billion of investments to build facilities in North America dedicated to manufacturing EVs and batteries, according to the Center for Automotive Research (CAR), a nonprofit think tank based in Ann Arbor, Mich.

In the first five months of 2022, automakers announced $24 billion in EV-related investments, almost double the investments announced by the same time last year.

Many automakers, interested in leveraging opportunities in the EV market, are investing in southern states due to lower energy costs, available workforce and livability. Between 2020 and 2021, southern investment jumped from $3 billion to $22.4 billion—outpacing the $1.4 billion to $9.9 billion investment in the Great Lakes region during that same period and climbing closer to the $36 billion last year in all states combined, according to a recently published CNBC analysis.

Design-Build a Better Manufacturing Facility

Like many of our manufacturing clients who push for maximum efficiency, the auto industry appreciates A M King’s Design-Build approach for many reasons: being its single point of contact, an easier purchasing process, fewer contracts and painless approvals in the construction phase. All in all, it’s a much more streamlined process that enables us to place projects on the fast track while staying on budget.

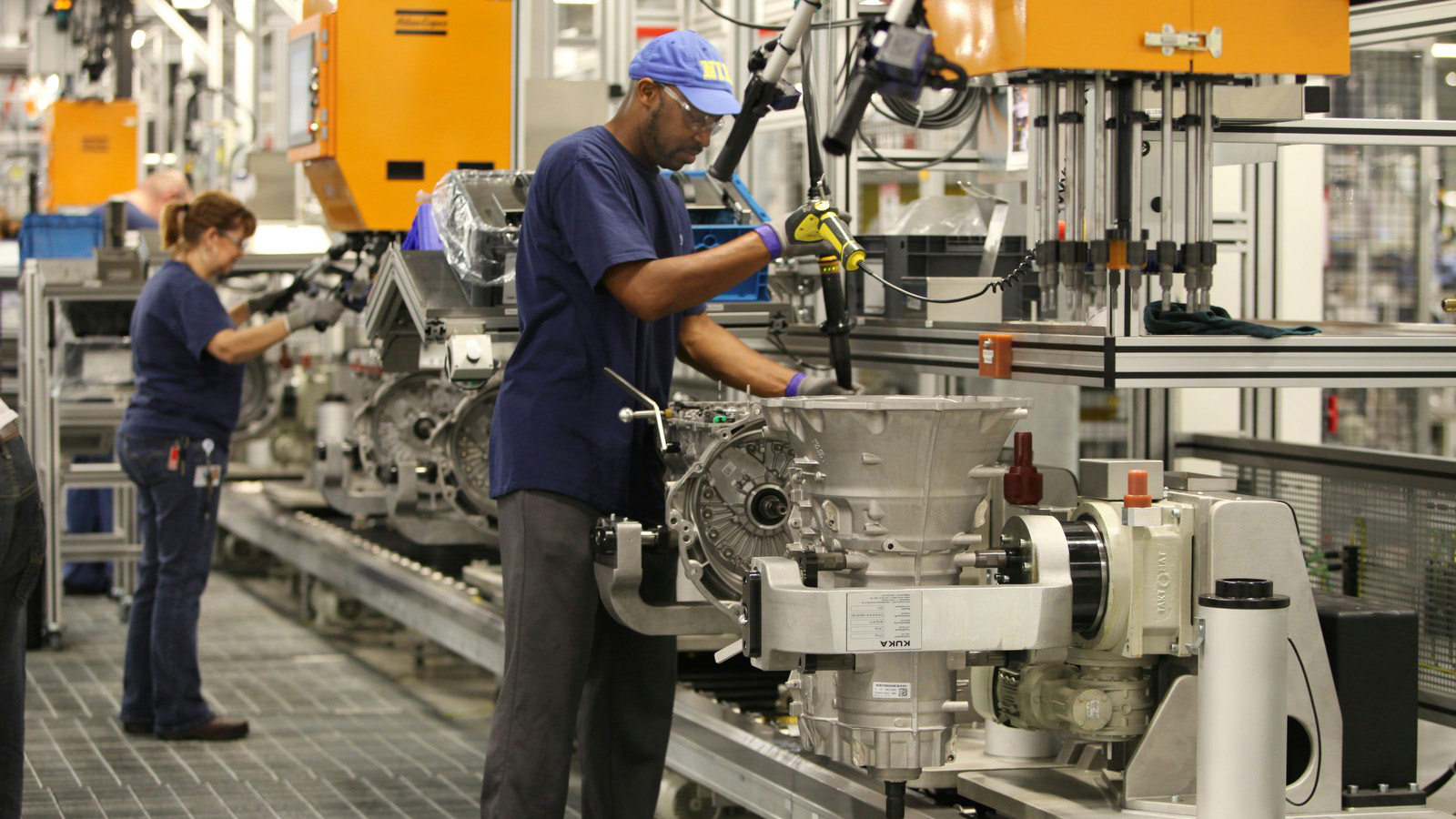

A M King recently completed two major capital projects for ZF Transmissions (ZFTG) in South Carolina — a state that is home to more than 600 automotive companies. ZFTG is the largest U.S. production plant owned by ZF Friedrichshafen AG (ZF), a German-owned global technology company that supplies systems for passenger cars, commercial vehicles, and industrial technology. The mega-facility has undergone several major expansions since launching production operations 10 years ago.

Last year, ZF Group received several large-scale orders worth several billion euros from North American vehicle manufacturers for its automatic 8-speed PowerLine transmission—including the largest individual commercial-vehicle-related order in company history. This announcement noted that production of an electric version will start in Gray Court next year. Consequently, ZF is expanding its transmission plant there, investing millions and creating hundreds of new jobs.

A Powerful Client Relationship

Our client partnership with the automotive supplier began approximately seven years ago. Each time we successfully complete a project, we are asked to do more. In an increasingly busy marketplace,

A M King has made ZF Transmissions a priority client because of the history of mutually beneficial projects.

This year, we began a multiphase project that started with conversion of an existing warehouse and distribution space into a new manufacturing area where ZFTG will produce transmissions for a worldwide leader in the EV market. Our scope of work included extension of utility lines that will eventually tie into new equipment.

The other project A M King started this year and recently completed involves an expansion of ZFTG’s Product Engineering Support Center (PESC) to accommodate new testing equipment for the company’s product lines. Designed to match the existing structure, the 6,000-sf test cell extension will also house infrastructure and support functions required to operate the testing equipment. The floorplan consists of two new Dyno test cell rooms leading to the electrical room. The extension will tie into the existing steel structure on one 100-foot wall.

In both of these projects, A M King was able to offer a Design-Build project approach which yielded typical advantages over traditional project delivery methods.

- We were able to order long lead items before the design was complete.

- Design-Build allowed constant collaboration with ZFTG’s engineering and facilities group.

- A M King’s deep experience in the manufacturing industry enabled our teams to correct a design specification before the design was complete.

- Submitting design and construction in one proposal eliminated 2-3 weeks of bid activity. The project was under budget and finished ahead of a fairly aggressive schedule.

A M King’s partnership with ZFTG supports the company in reaching their procurement requirements, allows ZFTG to glean cost and schedule information from the construction industry and assists them in better executing current projects, and planning for future projects. A M King will continue to partner with the automotive company on their projects with the goal being to add value to their automotive products.

Conclusion

The manufacturing industry presents many unique opportunities and complex challenges, many of which our experts can solve through our specialized Design-Build project delivery method. In addition, as many companies move towards more environmentally conscious processes, A M King accepts and executes projects with these objectives in mind. We desire long-term relationships versus transactional or one-off projects and will continue to offer project delivery that promises the best solutions for client growth.