A Lesson in Fall Protection from an Expert Superintendent

Several years ago, I was the field Superintendent on an expansion project in a rural area of Southern New York. I observed an iron worker placing metal decking on a roof penthouse more than 30 feet above the ground. His lanyard got caught, causing him to fall off the I-beam. Fortunately, he was wearing a body harness and we were able to rescue him within minutes. I attribute our quick response to the fall rescue plan we had established. He suffered no injuries and was able to return to work immediately after medical examination.

Stories like this can so easily end in tragedy. There are many high-risk areas on construction sites; concrete forms, ladders, scaffolding, scissor lifts and boom lifts are among the most common areas of concern. The challenge of enforcing fall protection is continued observation of the workers and the job site, ensuring that all the workers are following A M King job site safety rules and staying up-to-date on the latest OSHA regulations.

Tracking and learning from situations that could have been catastrophic shows promise in improving safety, with TRIR and DART rates reduced by 57 percent and 62 percent respectively at companies that do so—according to the Associated Builders and Contractors’ 2019 Safety Performance Report.

The stakes are high. “Fatal falls,” said the Bureau of Labor Statistics (BLS), “were at their highest level in the 26-year history of the Census of Fatal Occupational Injuries, accounting for 887 worker deaths,” 17% of all fatalities during 2017.

Falls remain the leading cause of work-related deaths in construction, with 42 percent of construction worker deaths involving falls, according to The Center for Construction Research and Training (CPWR). Last year the organization published results from a 33-year study that determined that almost half of the worker deaths in the construction industry were a result of a fall without proper fall protection. Data collected from 768 fatality reports filed within the NIOSH Fatality Assessment and Control Evaluation Program from 1982 to 2015 found:

- 325 of the fatalities involved falls

- 54 percent had no access to personal fall protection

- 23 percent had access to personal fall protection but did not use it

- A third of the falls occurred at 30 feet or higher off the ground

Updated OSHA General Industry standards took effect in 2017 (29 CFR 1910.28), clarifying the walking-working surface and personal fall protection standards, and there are tough consequences for non-compliance. Since Trump took office, OSHA has proposed some of the biggest penalties in recent years. Ten of the biggest construction industry fines, based on the most recent OSHA records available, range from approximately $1.5 million to a little more than $271,000. Fall protection and trench violations make a strong showing on the list.

In fact, Fall Protection – General Requirements is OSHA’s most frequently cited standard for the eighth consecutive year, the agency and Safety+Health announced late last year. There were 7,720 violations in that category.

OSHA does more than levy fines. It provides training, such as OSHA 30 Hour Training and sponsors special events such as the National Safety Stand-Down-To Prevent Falls in Construction, which will be held this year May 6-10.

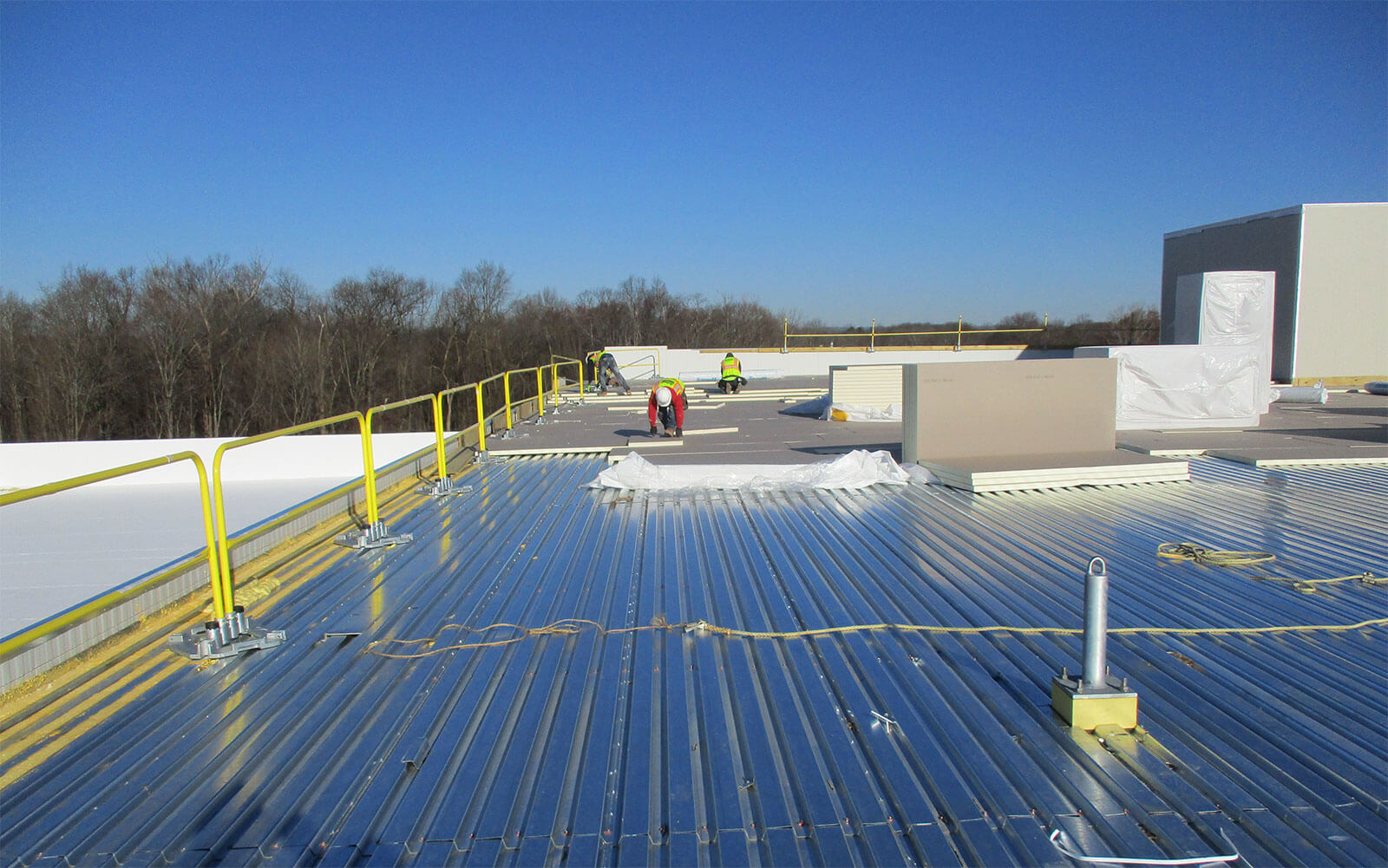

Of course, workers on my jobsites are OSHA certified, but I think it’s important to manage fall safety from a broader perspective. These are the components of an ironclad fall protection system:

- Ensure that all contractors have a competent person onsite at all times who is responsible for his/her workers.

- Meet with all contractors to review their site-specific fall safety program, knowledge and equipment prior to commencing work.

- Assess each phase of the project for potential fall hazards, implement any needed changes, and revise fall protection plans.

- Invite a third-party safety inspector to visit the site several times a month for unannounced safety inspections.

- Schedule onsite fall protection safety training sessions regularly during the project.

- Hold weekly safety coordination meetings and hazard specific toolbox talks with all workers.

- Require that all workers attend an A M King safety orientation prior to commencing work.

My experience ranges from building retail stores and restaurants to factories and cold storage distribution centers. With 30+ years in the construction industry, I have never had injuries or lost time due to falls on my jobsites.

Safety is my number one priority. I want to see every worker go home at night to his or her family–without injuries.